Updated - October 4, 2025 - Copyright - Ralph Gibson - 2014

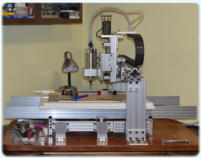

The CNC Mill

One of my favorite tools I have to tinker with is a CNC Mill that I designed and built

as shown below. This is a hybrid tool built up and based on two very different

system parts. The “X” axis was built using aluminum extrusions and hardware

from OpenBuilds. The “Y” and “Z” axis were built using aluminum extrusions and

hardware from 80/20 Inc. Most components used in the design were purchased

from Avid CNC, Automation Technology, Inc., and McMaster-Carr.

The original mill with +48VDC, 400W air cooled spindle

is shown on the left. On the right, is the mill upgraded

with a 240VAC, 1,500W ER11 water cooled spindle. The

new spindle is driven by a 2,200W VFD which provides

very accurate speed adjustment. The mill was designed

to be somewhat different than most examples I’ve seen.

The “X” table moves side to side, instead of the “Y”

crossbar moving. Mostly because I have some cabinets

above the mill that the “Z” axis would hit if the “Y”

crossbar moved. For manual operations on each axis, I used handles from Taig Tools that were used on

the Taig micro-mill that I own, as I find them very comfortable to use. Brass adapters for the Taig handles

I turned on my Taig micro-mill for the CNC mill.

For the CNC mill, I used 1/2”-10TPI ACME stainless steel threaded rod for the drive on each axis, that I

purchased from McMaster-Carr. With the 200 step per revolution stepper motors and 10TPI threaded rod,

the mill has a 0.0005” resolution per step. And since the controller for the mill supports micro-stepping,

the mill is extremely accurate and repeatable in use.

I use VCarve-Pro from Vectric to generate gCode to drive the mill, a Gecko G540 4-axis controller to drive

the stepper motors, and Mach3 CNC Control Software from ArtSoft to drive the Gecko controller. I

purchased the Gecko G540 controller with a 48V, 12.5A power supply, and chassis as an enclosure set

from Automation Technology, Inc. (KL-G540-48). Usually I draw up whatever I’m going to mill using Xara

Designer Pro X9 and export the drawing as a .AI file, which I can then import into VCarve-Pro.

I have fabricated limit switch mounting blocks but haven’t installed those as yet. A vacuum pickup head

and rotary table, have been designed and tested, and work great. The mill has about 20” travel in the “X”

axis, 15” travel in the “Y” axis, and 5” travel in the “Z” axis. Once I install the limit switches the travel will

be reduced by about one inch or so in each axis.

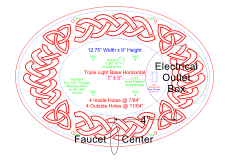

Home Milling Project:

A home milling project I did in early 2016 was to fabricate a base for a bathroom light fixture. The

electrical box for the light was installed before the cabinets with granite counter top were added.

Unfortunately, due to the cabinet layout, the sink couldn’t be centered under the outlet box, so there was

a 4” offset between the electrical box and the center of the sink as shown in the left photo.

I designed a lamp base using Xara Designer Pro X9 as shown, exported the design as an Adobe Illustrator

file, and then imported the file into VCarve-Pro. The mill parameters were set in VCarve-Pro and the

gCode files needed to drive the CNC mill were generated.

The bathroom lamp base was milled out of 3/4” Red Oak, 12-3/4” wide by 9” high. The width was set so

when the electrical box was covered, the center of the lamp was over the center of the sink and mirror.

The hole through the lamp base for the wires to pass through lined up with the left side of the electrical

box. The lower right photo shows the finished base mounted on the wall with the lamp installed.